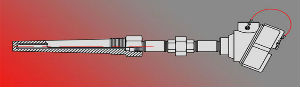

Industrial thermocouple assemblies are used in the process and power industries where thermocouples are installed in pipe lines or vessels. This type of assembly consists of three basic parts, the connection head, sensing element and thermowell or protection tube. Selecting the proper assembly involves consideration of several factors including process temperature, environment, fluid or gas pressure, pipe or vessel size and flow velocity.

Immersion thermocouples are used throughout all industries. They are generally inserted into or attached directly to the media to be measured. Instrument termination is available in a quick disconnect connector which is directly mounted to the end of the sheath or an epoxy filled transition securing flexible lead wires of various insulation depending on the conditions. Each type is available in a wide variety of configurations.

The higher signal output of RTDs make them easier to interface with computers and data loggers and reduces the effects of radio frequency interference. Industrial RTD’s are used in the process and power industry, pipe lines and vessels. The more commonly used configurations are listed on the following pages They represent only a small portion of Thermo Electric’s capability to manufacture quality products conforming to your specifications.

The standard RTD employs either thin film or wire wound bulb depending on the temperature range desired. The most common is the platinum, 100 OHM with a temperature coefficient of resistance of 0.00385 ohms/ohm/°C. Standard tolerance is a grade B to ASTM E1137. For tighter accuracy the grade A is available.

The higher signal output of RTDs make them easier to interface with computers and data loggers and reduces the effects of radio frequency interference. Industrial RTD’s are used in the process and power industry, pipe lines and vessels. The more commonly used configurations are listed on the following pages They represent only a small portion of Thermo Electric’s capability to manufacture quality products conforming to your specifications. The standard RTD employs either thin film or wire wound bulb depending on the temperature range desired. The most common is the platinum, 100 OHM with a temperature coefficient of resistance of 0.00385 ohms/ohm/°C. Standard tolerance is a grade B to ASTM E1137. For tighter accuracy the grade A is available.